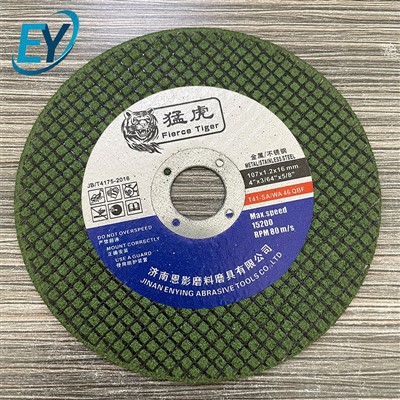

Cutting Disc

Jinan Enying Abrasives company was founded in 2011, the company is headquartered in Mingshui Street, Zhangqiu District, Jinan City, Shandong Province, professional export abrasive tools designated processing and sales factory, has passed the national quality management system certification, with 5000 square meters of modern standard production workshop, Equipped with a number of international leading automatic high-precision standard production lines, the annual production of all kinds of abrasive tools 50 million, the existing staff of more than 100 people, registered capital 50 million yuan, the existing national assets 60 million yuan. We have a professional R & D team, advanced production technology and design concept. "Create first-class brand, do first-class enterprise", truly let you not worry, rest assured, is our constant service tenet. Customer is our God, quality reputation is our forever pursuit goal. Welcome friends from all walks of life to visit Jinan Enying abrasives company to visit, guidance and business negotiations.

Why choose us?

Experience

In 2011, Enying company established its first professional sales team.

Production

A new factory was complete construction and jinan enying abrasive tools co.,ltd was established, with a modern standard production workshop of 5,000 square meters.

Technology

The annual production of all kinds of abrasive tools 50 million pieces.

R&D team

Enying Company is constantly developing and making progress. We firmly believe that the future of the company will be better and better.

Often cutting discs, also known as cut-off wheels, are made from a solid abrasive disc. These discs are often used for cutting metal; they are composed of an abrasive mix of grit and adhesive that is formed into a thin, rigid disc with fiber webbing running through it for strength.

Benefits of Cutting Disc

High resolution

Cutting slices can provide high-resolution images and data, and can detect tiny sample structures and features.

Non-destructive

Cutting slices can obtain the internal structure and information without destroying the sample, and can preserve the integrity of the sample.

Convenience and quickness

Cutting slices are a fast analysis tool, which can often be completed within a few minutes.

Diversity

Cutting discs can be applied to different types of samples, such as biological tissues, cellulose materials, metals, minerals, etc.

Material of Cutting Disc

Cutting disc for aluminum

Aluminum is a lightweight material, coming in at about one-third the weight of steel. It is also often just as strong or stronger when produced using the right techniques and correct alloys. In addition to a high strength-to-weight ratio, aluminum has a nice finish and natural resistance to corrosion. This metal offers significant advantages, but working with it presents unique challenges. Aluminum has a low melting point and will load on abrasives.

Cutting disc for stainless steel

Stainless steel contains chromium, which gives this metal a protective layer against corrosion. Stainless steel resists but is not totally impervious to rust, so steps need to be taken during the production and fabrication process. It is essential to choose a cutting wheel made from abrasives compatible with stainless steel to ensure the workpiece isn't contaminated. The right cut-off wheel for stainless steel will increase efficiency, reduce rework and eliminate cross-contamination.

Cutting disc for steel

Compared to metals like aluminum and stainless steel, sheet metal is much easier to cut through. With sheet metal, the primary thing to consider is the wheel thickness. Thin (.045 inch) and ultra-thin (1 millimeter) wheels are best. These wheels remove less material at once to provide a faster and cleaner cut that creates less friction and generates less heat, reducing the chances for surface discoloration.

General fabrication

In general metal fabrication, 0.045-inch wheel diameters are common choices. With thinner materials, an operator may want to choose a 1-millimeter disc instead for greater precision, less heat generation, and fewer burrs that will require removal before welding. The choice of grain will likely depend on the material composition of the workpiece — higher-performing grains for structural steel and difficult-to-cut metals, contaminant-free discs for stainless steel.

Pipe fabrication

In metal pipe fabrication, the choice of cutting disc often depends on the diameter of the pipe to be cut. For a 3/4-inch or smaller pipe, a 4 1/2-inch diameter will usually be sufficient. For a pipe of up to 2 1/2 inches, a 6-inch cutting disc is effective, and for a pipe of up to 3 1/2 inches, a 9-inch cutting disc is often most suitable. It's also advisable to choose the thinnest disc possible to minimize heat and friction and to use a type 1 wheel for a deeper cut unless the application imposes a particular constraint. For larger pipe often found on the pipeline, a depressed-center cutting disc provides added clearance when working at a constrained angle, and 0.045-inch disc thickness is ideal for cutting applications in fabrication yards or on the right of way for field repairs.

Shipbuilding

When an operator is working on the confined, hard-to-access spaces of a ship, making a cutting disc last as long as possible is often a priority. For this reason, the operator will often want to choose a harder, potentially longer-lasting wheel. However, when operators must use air tools whose hoses have stretched over long distances to access difficult areas of the ship, the tools may be underpowered. In this case, wheels with a soft bond will be ideal because they make it easier to maintain a fast cut. In shipbuilding, the work material often influences the cutting wheel selection. When working with aluminum, an operator may want to select a cutting disc that will not load or gum up.

Welding preparation

Preparing for welding typically involves exact metal cutting. With a basic cut-off operation, precision is not critical, but with complex work or repairs that need to preserve the initial aesthetic qualities of the material, precision can save time and money. Using a 0.045-inch cutting disc — a little more than a millimeter thick — is common in welding to allow for precise and accurate cuts.

Railways

Modern railways use hard-to-cut alloy steels, so a high-performance cutting disc is necessary for high-speed gas saws. A self-sharpening zirconia alumina grain that retains a high cutting performance throughout the life of the wheel offers excellent performance.

Construction

Building and construction sites feature a wide variety of metal cutting applications. Operators often look for a disc that can do it all, from cutting off rebar to making long cuts on sheet metal. Many times, an aluminum oxide disc provides the right mix of versatility, performance, and price.

How to Use Cutting Disc With Right Way

Wear protective gear

Before using a cutting disc, make sure to wear the proper protective gear. This includes safety glasses, gloves, and long-sleeved clothing. The gear will shield you from flying debris and prevent injuries.

Choose the right disc

Different cutting discs are used for different materials. Use the disc that is appropriate for the material you’re cutting. For example, a metal cutting disc won’t be effective on concrete, so make sure to use the correct disc.

Check the disc before use

Inspect the cut-off wheel before using it. Look for any cracks, chips, or other signs of damage. Using a damaged disc can cause it to break apart and hurt you. If the disc is damaged, replace it with a new one.

Secure the workpiece

Make sure that the workpiece is securely held in place before attempting to cut. This will ensure that the material doesn’t move or wobble during the cutting process, which can damage the workpiece or throw off the cutting wheel.

Use proper cutting technique

Hold the cutting disc at a 90-degree angle to the workpiece. Apply gentle pressure to the material while cutting, letting the disc do the work. Allow the disc to cool down after a few cuts, so it doesn’t overheat and become less effective.

Turn off the disc before stopping

After you’ve completed the cut, turn off the disc before releasing any pressure. This will prevent the disc from spinning out of control and causing damage or injury.

How to Maintain Cutting Disc

Check the label

Always check the label on the cutting disc to ensure that it is the correct one for the job. The label will provide information about the disc's size, speed, and intended use. Never use a cutting disc that is not designed for the material you are working with.

Check for damage

Inspect the cutting disc for any visible signs of damage. Look for cracks, chips or signs of wear that could cause the disc to break during use. If any damage is found, replace the cutting disc immediately.

Check for wear

Cutting discs wear out over time and need to be replaced when they become too small or thin. Look for signs of wear such as a reduction in diameter or thickness. If the disc is too small or thin, it may break during use.

Check the arbor hole

The arbor hole in the center of the cutting disc should fit snugly onto the tool's spindle. Check the diameter and shape of the arbor hole to ensure it matches the spindle size and shape.

Check the maximum speed

Cutting discs are designed to operate at a specific maximum speed. Check the disc's maximum speed rating and make sure it matches the speed of the tool you are using. Over-speeding the disc can cause it to break apart and cause injury.

Store the cutting disc properly

After use, store the cutting disc in a dry, cool, and safe place. Discs should be kept out of reach of children and away from sources of heat or moisture.

Disc type

- The type of cutting disc you use lays the groundwork for your project's success. Each type excels in specific tasks and materials. Understanding these distinctions guarantees a safe and successful project with the best-cut quality.

- These are three common metal-cutting disc types:

- Aluminium oxide and silicon carbide are the materials that make these discs the workhorse of cutting. They expertly tackle steel, stainless steel, cast iron, and more. Although reliable, they generate heat that may cause minor warping or hardening.

- Diamond discs are studded with industrial diamonds set in a metal or resin base. These powerhouses effortlessly slice through hard, abrasive materials like ceramic, tile, and stone.

- It is also possible to use them for thinner metals, such as aluminium and copper, as long as you are cautious. Diamonds produce a lot of heat.

- Carbide-tipped discs combine super-strength carbide tips with a steel or aluminium base. It's the perfect tool for cutting thick or hardened steel.

- While pricier than abrasive or diamond discs, they reward you with durability and precise cuts.

Material compatibility

Great cuts require discs with the right grit and bond. It ensures smooth operation, less risk of accidents, and a flawless finish.

Here are some disc options tailored to specific metals:

- Steel: In most steel-cutting jobs, abrasive discs with tough aluminium oxide or silicon carbide grains are suitable. For heavy-duty work, carbide-tipped discs are your best bet.

- Stainless steel: Discs with a harder bond and finer grit protect stainless steel's finish and prevent corrosion. In some cases, diamond discs are the right choice.

- Aluminium: Thinner discs with aluminium oxide or silicon carbide abrasives paired with a suitable bond are the way to go with aluminium. While diamond discs work, keep those speeds lower to avoid overheating the metal.

- Cast iron: Consider strong, coarse-grit abrasive discs for handling cast iron. Choose carbide-tipped discs for heavy-duty cutting.

Disc size

- Size matters when cutting discs. The disc diameter is crucial to performance, safety, and efficiency.

- Make sure your disc fits your tool and is suitable for the size and thickness of the material. It guarantees the cutting depth and keeps your equipment in top shape.

- Metal cutting discs typically range from 4 to 14 inches in diameter. Make sure the disc size is right for your cutting tool.

- For example, Angle Grinders handle discs from 4 to 12 inches. The cutoff saw is efficient for large projects and requires 12 to 14-inch circular saw blades.

Thickness

- Cutting disc thickness is all about stability, wear resistance, and cutting speed.

- Thicker discs are effective and last longer but might sacrifice speed, while thinner discs cut fast but wear out more quickly.

- Thick Discs are known for power and durability. In jobs requiring tough materials or extended cutting, thicker discs provide more stability. They resist bending and handle the heat of a hard day's work.

- Thin Discs are known for precision and speed. Thinner discs are better for fine cuts or when speed is critical. Their smaller profile dissipates heat quickly and leaves cleaner edges, ideal for careful craftsmanship.

- Remember, thickness is a trade-off. Thinner discs may save you money, but they wear out faster. Thicker discs last longer, saving replacement costs over time.

Speed rating

- Every cutting disc has a maximum safe RPM (revolutions per minute) rating. It is not a suggestion – it's vital for your safety.

- Using a disc at speed higher than its rating can lead to catastrophic failure – the disc could shatter, causing severe injuries.

- Always check the maximum RPM of your cutting tool and the disc's speed rating. Never exceed the disc's rated speed. Matching tool and disc speeds ensure:

- Every cutting tool has an RPM limit, and you should know yours. Inspect your disc and look for the speed rating printed on it. Never use a disc rated below your tool's RPMs.

- Once you know the numbers, pick a disc rated the same as or slightly higher than your tool's limits. That gives you a safety buffer.

Quality and brand

Regarding cutting discs, quality, and brand reputation are more than buzzwords. They impact safety, performance, and disc longevity.

Investing in trusted brands means you get the following:

- Rigorous testing: A reputable brand puts its discs through multiple layers of testing, so you know they are reliable.

- Precision manufacturing: Quality brands mean superior materials and construction, leading to clean cuts and longer disc life.

- Support and warranties: It will be helpful to have someone by your side if anything goes awry and you need assistance.

Application

- Cutting discs are specialised tools for a specific purpose. The type of work you're doing will determine the right disc size, material, thickness, and more.

- Is it steel, aluminium, wood, or even plastic? Different discs are designed to handle specific materials. An unsuitable disc can shorten its life and cause poor cut quality.

- You can choose particular discs for specific applications. For example, cutting discs for woodworking demands specific features like tooth design, kerf width, and those that prevent kickback.

- If you are cutting plastic, you should choose discs designed specifically to prevent heat build-up and melt.

- When cutting aluminium, use thinner discs with aluminium oxide or silicon carbide abrasives.

Safety features

- Cutting discs are powerful tools, and safety is non-negotiable. Here's what to look for:

- Look for discs with extra reinforcement, especially for demanding tasks. These are more resistant to breakage under stress.

- Some discs come with coatings that reduce heat buildup and sparks. Such safety features can prevent injuries and accidents.

Cost

- Cost is always a factor, especially when dealing with project budgets. It's tempting to grab the cheapest cutting discs. But remember, you usually get what you pay for.

- Higher-quality discs might have an upfront price tag, but they often last longer, cut better, and are safer. Long term, this can save you money.

- The price of cheap discs may seem attractive. Still, you may have to buy replacements sooner, waste more material with sloppy cuts, or risk injuries.

- Finding the right balance is crucial. Consider your project carefully and determine how much you should invest in your discs.

Certifications

Our Factory

A new factory was complete construction and jinan enying abrasive tools co.,ltd was established, with a modern standard production workshop of 5,000 square meters. With a number of international leading automatic high-precision standard production lines, the annual production of all kinds of abrasive tools 50 million pieces.

Enying Company is constantly developing and making progress. We firmly believe that the future of the company will be better and better. We also hope that we can leave a perfect cooperation with you in our company history.

FAQ

As one of the most professional cutting disc manufacturers and suppliers in China, we're featured by quality products and good service. Please rest assured to wholesale customized cutting disc at competitive price from our factory. Contact us for more details.

Abrasive Fiber Disc, , Flap Disc